The pharmaceutical industry is one of the most heavily regulated industries in the world. Due to the nature of its products, stringent safety protocols must be always followed. Therefore, it is essential that all materials and equipment used in the production of pharmaceuticals, including a long lasting industrial stainless steel hose are of the highest quality, including hoses. Industrial hoses are a vital component of the pharmaceutical production process and must be chosen carefully to ensure the safety of the products and the workers who handle them. In this blog post, we will discuss the importance of using the right hoses in the pharmaceutical industry.

The Different Types Of Hoses Available

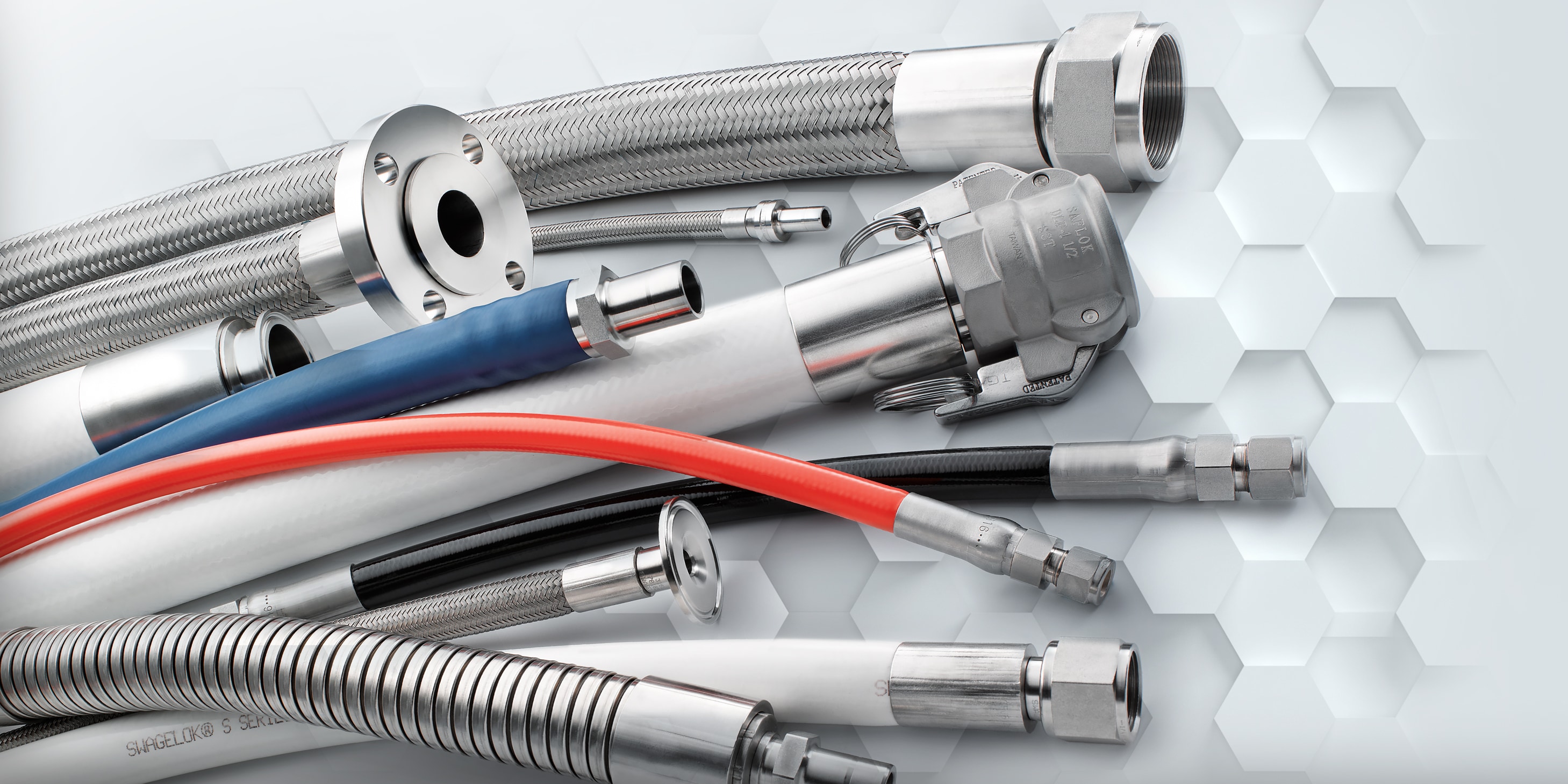

When it comes to the pharmaceutical industry, it’s important to use the right hoses for your needs. Depending on the type of applications or processes you need to run, there are a variety of hoses available for use, such as a long lasting industrial stainless steel hose. Here are some common types of hoses that you can find in the pharmaceutical industry:

- Metal Hoses: Metal hoses are often used when dealing with hazardous materials, such as corrosive liquids, steam, and acids. They are made from a range of materials, such as stainless steel, aluminium, and titanium.

- Plastic Hoses: Plastic hoses are generally used in applications where there is a need for flexibility and resistance to abrasion. They are typically used in areas where static electricity could be a hazard.

- Rubber Hoses: Rubber hoses are typically used in applications that require flexibility and good resistance to chemicals and acids. They come in a variety of sizes and shapes and are ideal for transferring liquids, gases, and solids.

- Silicone Hoses: Silicone hoses are typically used in applications that require extremely high temperatures or cryogenic conditions. They can handle extreme temperature ranges, from -90°C to +260°C.

It’s important to choose the right hoses for your specific needs in the pharmaceutical industry. It’s important to take into account the type of materials being handled, the temperature requirements, and any other factors that may affect your choice.

Why Hoses Are Important In The Pharmaceutical Industry

Hoses play an important role in the pharmaceutical industry, as they are used to transport chemicals and other materials in a safe and effective manner. Hoses must be able to withstand the corrosive and hazardous materials used in the pharmaceutical industry, making it essential to choose the right kind of hose. Long lasting industrial stainless steel hoses are ideal for this purpose due to their durability and resistance to corrosion.

Using the correct hoses is essential to ensure the safety of those working with the materials, as well as ensuring that products are delivered efficiently and securely. Industrial stainless steel hoses are designed with a protective coating which makes them highly resistant to corrosion and damage from hazardous chemicals. The longevity of these hoses also means that they can be used for extended periods of time, reducing the need for frequent replacements.

In addition to their durability and corrosion resistance, long lasting industrial stainless steel hoses are also lightweight, allowing for easier manoeuvrability and transport. They are also highly flexible, making them ideal for transporting materials around tight corners or difficult spaces. This flexibility also makes them easier to store when not in use, further reducing costs associated with replacement and maintenance.

Industrial stainless steel hoses are an essential tool in the pharmaceutical industry, providing a safe and effective means of transporting materials while ensuring longevity and cost-effectiveness. The use of long lasting industrial stainless steel hoses is a vital step towards maximizing productivity and minimizing risk.

How To Choose The Right Hoses For Your Needs

Choosing the right hoses for your pharmaceutical industry is essential for a safe and efficient operation. Different types of hoses have different purposes and it’s important to choose the best ones for your specific needs. Here are some things to consider when selecting the right industrial hoses for your operations:

- Temperature: You need to make sure that the hoses can handle the temperatures of the materials you’ll be working with. Different types of hoses can withstand different temperatures, so it’s important to check the specs of the hose before purchasing.

- Pressure: The pressure of the materials being transported will also affect the type of hose you use. Make sure that the hoses you choose can handle the pressure of the material, otherwise they could be damaged or cause damage to other equipment.

- Flexibility: Depending on the application, you might need a more flexible hose or a stiffer one. Make sure to take into consideration where and how the hoses will be used so that you can choose the right flexibility for your needs.

- Abrasion Resistance: If the materials you’re transporting are abrasive, you need to choose hoses with strong abrasion resistance so that they won’t wear down quickly.

- Chemical Compatibility: Some chemicals can be corrosive, which means you need to choose hoses with chemical compatibility. Make sure that the hoses you’re using are suitable for the chemicals you’re working with.

Once you’ve considered all these factors, you should be able to choose the right hoses for your needs. However, if you’re still uncertain, it’s best to consult with an experienced professional who can help you find the right solution for your needs.

The Benefits Of Using Hoses In The Pharmaceutical Industry

Using hoses in the pharmaceutical industry can have numerous benefits, and it is important to ensure you are choosing the right ones. The most obvious benefit of using hoses is that they help ensure the safe and efficient transfer of products. High-quality industrial hoses provide an added layer of protection against spills and leaks, helping to protect both people and equipment. Furthermore, the right hoses can help improve the efficiency of your production process and reduce downtime due to maintenance.

Additionally, using industrial hoses can also provide a cost savings in the long run. High-quality hoses require less maintenance and are less likely to need replacing, which helps keep operational costs down. Industrial hoses are also able to stand up to extreme temperatures, which is important when dealing with sensitive products. By using hoses with temperature ratings suited for your particular application, you can be sure that your products are kept at the optimal temperature for processing and storage.

Finally, using hoses in the pharmaceutical industry can help ensure safety and product integrity. Hoses that are designed for this sector are often constructed from materials that meet FDA requirements and come with various certifications. This helps ensure that no contamination or other health risks occur during transfer. By using these hoses, you can rest assured that your products remain safe and of the highest quality throughout their journey.